Study: How Sauna Wall Panels Heat Up

Saunologia conducted a study on the heating of sauna wall panels. The question was whether the panel installed on an air-gap insulated wall heats up entirely or only on the warm side. Temperature sensors were installed on one wall of an indoor sauna, along a single vertical line, on both the inside and outside surfaces of the panel. The measurements revealed that the surface temperatures of the panel were nearly identical on both sides of the wall. This unique observation highlights that wall paneling, like the benches, is a part of the sauna that heats up and radiates heat once warmed.

Research Methods

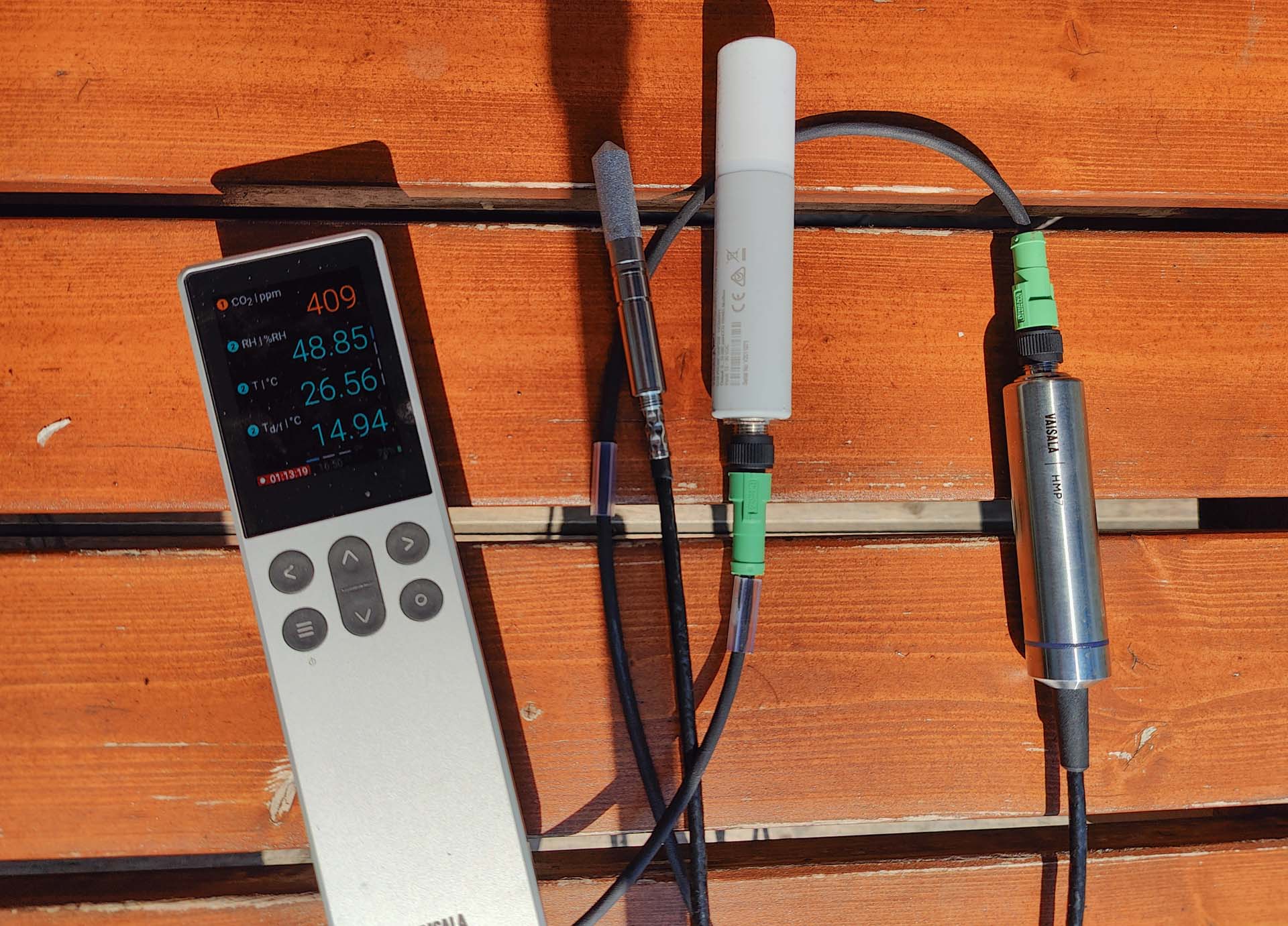

During the construction of the sauna at Saunologia’s headquarters, K-type thermocouples (temperature sensors; RS Pro Z2-K-2.0-1/0.2-MP), were installed in the air gap of the wall paneling (the gap between interior paneling and the insulation/vapor barrier surface). Four separate thermocouples were placed along the same vertical line in the middle of the vertical studs, on the wall diagonally opposite the electric sauna heater. The placement aimed to minimize the effect of the direct heat radiation from the heater on the wall heating.

The thermocouples were attached to the inner surface of the panel, facing the air gap, with pieces of aluminum tape at heights of 500, 1000, 1500, and 2000 mm from the floor (appr. 20”, 40”, 60” and 80”). The ends of the thermocouple wires were left hanging from the bottom of the paneling just above the floor level so that the temperature could be read with a meter. The Fluke 561 meter used had a measurement accuracy of one degree Celsius.

For the test, identical meters were attached to the room-facing side of the paneling along the same vertical line at corresponding heights, using the same aluminum tape. Before the test began, the baseline temperature of all sensors was checked and found to be the same within an accuracy of one degree.

The wall panel was made of thermally treated aspen with the Finnish Cent Dyyni (Dune) profile. This type of panel is thin, with a thickness varying between 9.5 and 15 mm depending on the profile, resulting in an average thickness of about 13 mm (just over ½”). The air gap thickness in the wall is 22 mm, with a 3 mm ventilation gap at the butt joint with the ceiling paneling.

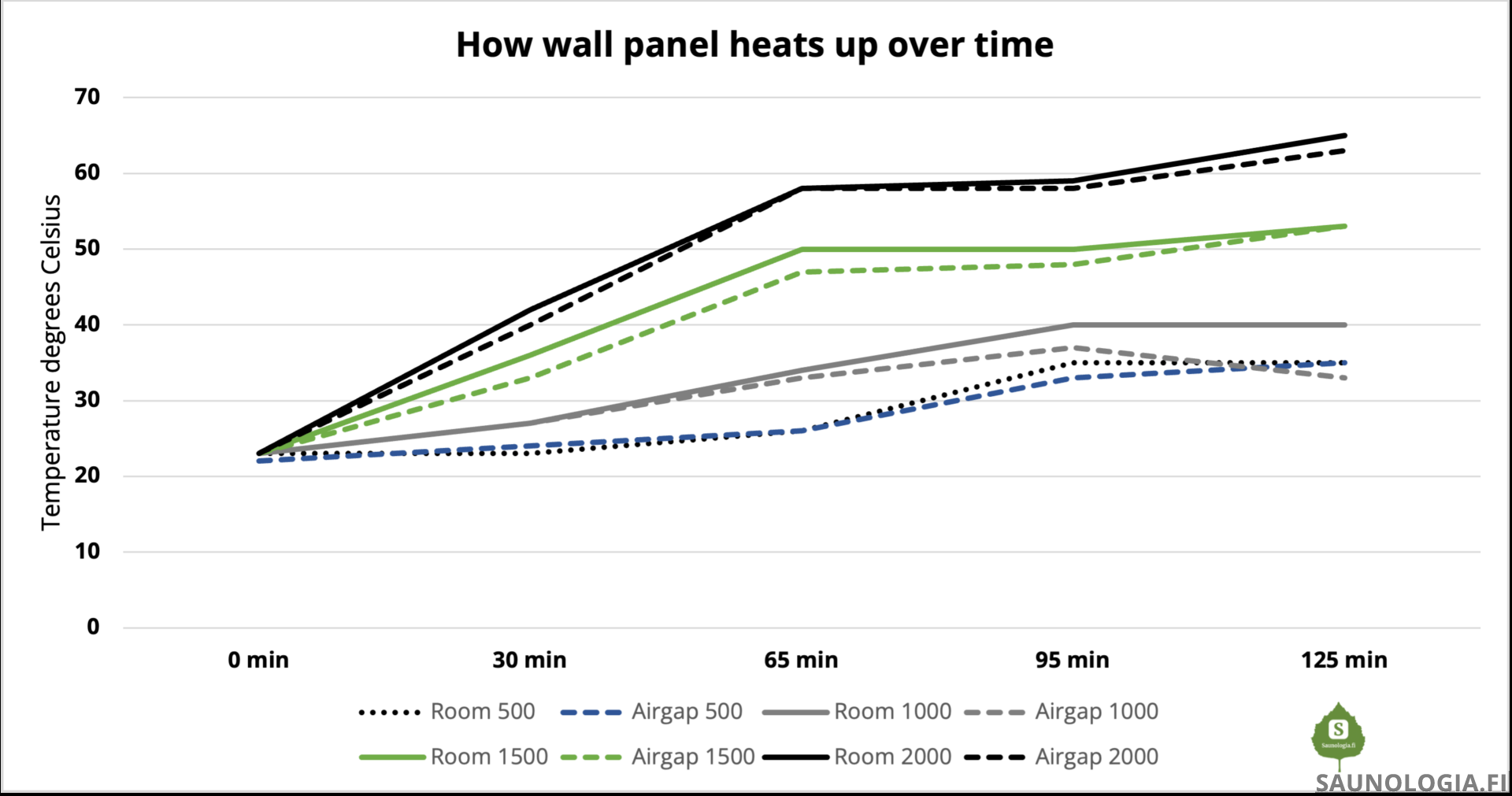

During the test heating, the electric sauna heater was started normally. The temperatures from the thermocouples were recorded at 0, 30, 65, 95, and 125 minutes. The electric heater’s (Saunum Primary, equivalent of North American Air) convection function was used during the sauna session, and its effect might be visible in the 90 and 120-minute measurements.

The temperature readings presented in the results are based on a single test heating, but the measurements were repeated twice with the same results, although time series were not fully recorded in the repeat measurements.

Results

The test showed that the temperature of the inner and outer surfaces of the wall panel was almost identical at all measurement times and at all points along the wall at different heights. There were four measurement points and five timestamps, resulting in 20 data points. Of these, in 19/20 data points, the inner surface temperature was at most 3 degrees lower than the outer surface. Except for one data point, the inner surface was always either as warm or cooler than the outer surface, never warmer. The relative differences between the inner and outer surfaces did not change over time. This can also be seen in the accompanying chart.

From the time series, it can be observed that using the convection function between 65 and 95 minutes stopped the heating of the sauna in the upper part (1500 and 2000 mm) but enhanced it at lower levels (500 and 1000 mm). On the other hand, the convection function did not appear to affect the relative differences between the inner and outer surfaces.

What do the results mean?

Based on this test, it seems that the paneled walls of the sauna heat up evenly throughout. This observation refines our understanding of the sauna’s energy balance. Specifically, it suggests that the massiveness of the sauna’s wall paneling must be considered in the sauna’s energy needs. Based on the results, one could argue that the thicker the paneling used, the more energy is required to heat the sauna’s structures.

In a way, the results also support the idea of how the air gap works. When the air in the gap is warm or hot, it ensures that the paneling dries thoroughly after use.

What is the real significance of the air gap?

The air gap is one of the relatively new ideas in Finnish sauna construction. In the era of log buildings and outdoor saunas with massive walls, there would have been no place for it. The situation has been different during the time of indoor saunas and multi-layered wall structures. The air gap has been considered important for building health, as it ensures that the impermeable boundary (the vapor barrier) and the surface material layer above it stay dry. The rationale is that if moisture condenses on the outer surface of the vapor barrier, it can evaporate into the air in the gap.

Some enthusiasts have interpreted the air gap as an insulating layer, especially if reflective aluminum foil is used as an air barrier. For instance, Bert Jalasjaa’s book on sauna construction claims this triples insulation effectiveness. According to this study, the air gap’s significance for insulation is limited. If the wall’s inner material heats up throughout and air moves somewhat in the gap, the gap’s primary function remains keeping the paneling dry.

On the other hand, this does not invalidate all energy claims. In the later stages of sauna use, it may be energy-efficient to have air between the hot wall structure and the insulation/vapor barrier layer, as this slows down heat transfer by conduction through the assumedly slow-moving air layer.

Due to the panel’s rapid heating, I believe in the air gap’s importance in the heating of the panel. At all time points, the inner side of the panel heated up almost simultaneously, rather than, for example, the upper measurement points showing a delayed temperature increase. This is why I believe that the heating is not solely due to heat conduction from the room side of the panel but that heat is also transferred through the air gap.

Ideas for further research

This study was a pilot in nature. It can inspire several related follow-up studies. The most interesting of these would be to study the same panel on a wall without an air gap. This would clarify the air gap’s significance for panel heating. Currently, this remains uncertain, only speculative, as the sample material, thermally modified aspen, is extremely lightweight and therefore inherently insulating. This leads to the next suggestion for follow-up research, which would be to test the heating of paneling of different thicknesses or wood types.

GPT-4o was used in the translation of this article from the Finnish original.

Very good.

I wonder what happened w/ Airgap 1000 @ 125 minutes?

I wondered that myself, but that’s the figure I read two times.

There’s always an error component and random variation, otherwise it’s not empirical science